Why Need an Electric Wood Hammer Mill?

As we all know, wood pellet machine is the key part for making sawdust into bio-pellets. While not all materials are suitable for pelletizing directly, for some materials with diameter larger than 5mm, you need to grind them into sawdust or powder particles first. An electric wood hammer mill can help you grind large wood branches or straw stalks into small mesh size. We supply two types of wood hammer mill, the difference between electric wood hammer mill and diesel wood hammer mill is the engine — the former is motor while the latter diesel engine. You can choose anyone on the base of your cheaper energy resource. Besides, you can also take wood crusher into consideration according to your raw material. If your materials are wood logs, you need to use wood chipper for preprocessing prior to a wood crusher or wood hammer mill.

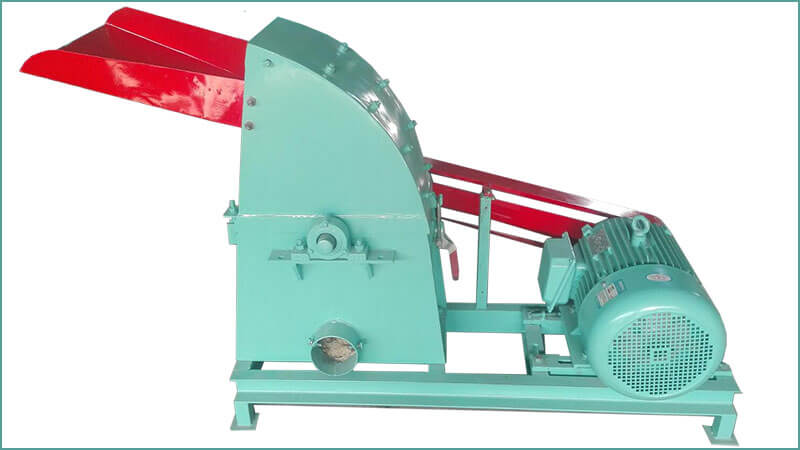

| CF158 wood hammer mill

|

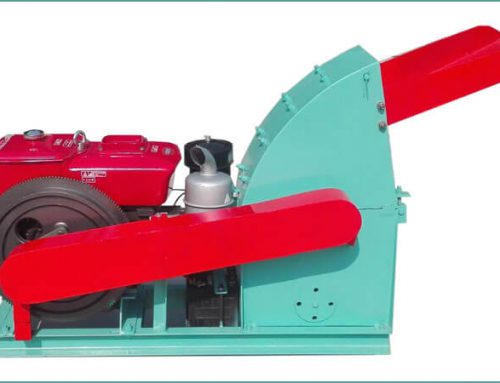

CF198 wood hammer mill

|

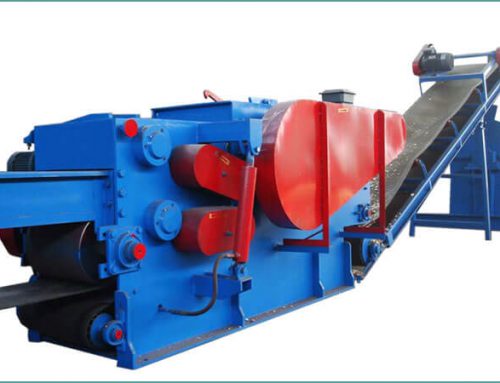

CF500B wood hammer mill

|

Features and Advantages of Electric Wood Hammer Mill

1. Electricity-saving: the smallest wood hammer power is only 2.2kw, best choice for home use.

2. Safe to operate, low noise, stable working.

3. Low malfunction rate, easy to operate and low maintenance cost.

4. Could process raw material in different or irregular size into even wood particle size.

Application of Electric Wood Hammer Mill

1. Raw material: Electric wood hammer mill is suitable for processing relatively soft raw materials such as wood branch, wheat straw, corn stalk, cotton stalk, etc.

2. Electric wood hammer mill can be used in wood pellets production, biomass briquettes production, animal feed pellets production or papermaking industry.

Wood Crusher Specifications

|

Model

|

CF158

|

CF198

|

CF420

|

CF-420C

|

CF500B

|

|

Power

|

2.2kw

|

4kw

|

7.5kw

|

11kw

|

22kw

|

|

Voltage

|

single phase/ three phase

220v/50Hz

|

three phase 380v/50Hz

|

three phase 380v/50Hz

|

three phase 380v/50Hz

|

three phase 380v/50Hz

|

|

Capacity

|

60-120kg/h

|

200-300kg/h

|

200-500kg/h

|

200-700kg/h

|

800-1100kg/h

|

|

Screen Size

|

360*160mm

|

510*200mm

|

680*280mm

|

680*280mm

|

820*390mm

|

|

Cross Dimension

|

48*58*63cm

|

97*75*64cm

|

112*82*107cm

|

112*82*107cm

|

124*97*106cm

|

Leave A Comment