1T/h EFB pellet Plant Introduction

If you are planning to build your own EFB pellets plant, we strongly recommend that you choose this production line, since this is the most popular EFB pellet production configuration. This 1T/h EFB pellet production line has compact structure, so it is easy to operate and of high performance. Besides, the key parts adopt high quality alloy steel adds wear-resisting material, prolong service life of 5 to 7 times, greatly reduce your production cost and expenses.

Specification for EFB Pellet

★ Moisture < 12%

★ Ash Content = 5%

★ Volatile Material = 75%

★ Carbon Content = 13%

★ Heat Energy = 4000 kcal/kg

Main Application for EFB Pellet

☞ Power Plant

☞ Boiler

☞ House Hold BBQ Rack

☞ Centralize Steam boiler

Features of 1t/h EFB Pellet Production Line

★ This EFB pellets production line can perfectly solve the tricky problem of EFB being material with long and hard fiber and high moisture content for pelletizing.

★ The equipment can be strictly set and customized.

★ With consecutive and reasonable process routing, each standalone machine is of high efficiency and low power consumption.

★ Electric control system makes the operation of whole production line much easier.

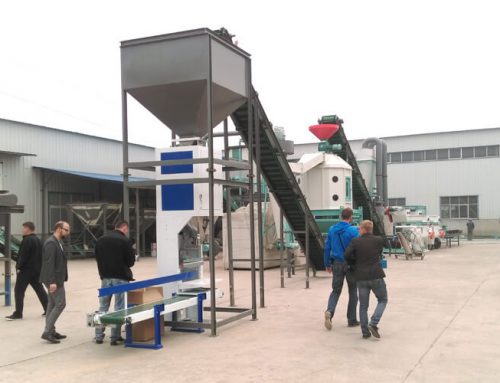

For 1t/h EFB Pellet Plant, we Equip the Following Machines

This empty fruit bunch shredder is a drum-type machine to improve the used EFB utilization rate, and it can process the EFB into fiber status, mainly used for the massive EFB that is not easy to process for its hard fiber texture.

2. Rotray Drum Dryer for EFB Fiber

The best moisture content to pelletizing is about 13-15%, while the moisture content in EFB is about 50%~60%, so drying process is necessary before making into renewable pellets to meet the energy demand of industries. Our Rotary Dryer is specially designed for drying EFB material, which can realize to reduce the moisture from 60% to 10% one time in large scale. Besides, its stove is fueled by sawdust, wasted wood, coal, which can save electricity consumption largely.

3. AZS-CF1000 EFB Fiber Crushing Machine

EFB fiber crushing machine is technically applied to crush the EFB fiber into small pieces for pelletizing process. Usually this machine can be combined with the EFB shredder machine. The materials for processing is delivered by conveying belt; equipped with high-intensity magnetic separator to sieve metals to avoid damaging the cutter, and safety vertical-roller to avoid hand injury.

4. MZLH420 EFB Pellet Mill

MZLH Wood Ring Die Pellet Mill is the most suitable for compressing high density biomass materials such as hardwood, palm fiber and EFB (empty fruit bunch).It has the following features

A. Main drive adopts high accurate gear drive, with an output of about 20% higher than belt drive.

B. Special design of feed conditioner adopts the frequency-conversion speed regulating control to guarantee EFB pellets quality.

C. The international advanced compensation type flexible coupling is of novel and compact structure, safety, low noise and less trouble.

5. SKLN1.5 type Biopellet Cooler

After the pelletizing process, the temperature of the EFB pellet is about 60-80 degree and the moisture content about 15%, so a Cooler is needed to reduce about 3-4% moisture, so that the EFB pellet is easy to store. In order to satisfy the different need from different clients, we develop one kind of new SKLN Counter flow Cooler. Obvious cooling effect, no cooling dead angle, and the finished product temperature can be less than 3℃ to 5℃ higher of the room temperature, so this cooler is your first choice for cooling EFB pellets. One SKLN1.5 type counter flow cooler is included in this production line.

6. DCS-25 CS1 Pellet Packing Machine

After cooling, the packing process is necessary to protect the EFB pellet from damp and dust. In this process, we assemble our best packing machine to you. This packing machine adopts two weighing bodies and high speed weighing system, can be used alternately or simultaneously, high efficiency and flexibility.

|

|

|

Note: Each standalone machine will be designed and manufactured in accordance with the demands of clients. Installation will be carried out and guided by professional technician. If you are interested in or any query of this EFB pellets production line, please always contact us freely.

Get know more about EFB Pellets

Palm trees are extensively planted across tropical areas of Asia, Africa and South America. Palm fiber, empty fruit bunch (EFB) and palm kernel are the main by-products of palm oil extraction. They are kind of well known biomass materials. The finished EFB pellets are efficient and clean when burning. A small volume of burning can produce a large amount of heat. Now, they have wide applications such as power plant, boiler, house hold BBQ rack, or centralize steam boiler. Therefore, pelletizing EFB fiber into pellet fuel can save you a lot of energy and help you make profit.

Superiorities of EFB pellets made by our pellet machine

▶ Low moisture in nature. The moisture of EFB pellet is around 8-12% whereas it is 50-60% for original EFB/palm fiber. This also means the saving of transportation cost because of the reduced weight of moisture.

▶ Higher heat value and efficiency. Since the EFB pellets are dryer than fiber, they are also more fully burned and can release more efficient heat instead of wasting energy for heating the extra moisture in fiber.

▶ EFB pellets are easy to handle or store because of their smaller volume and higher density.

▶ Suitable for most boilers. The diameter of EFB pellets are normally around 8mm while length is about 20-30mm, so they are suitable for most boiler input grate.

▶ EFB pellets generate low or no smoke while burned. As a result, you needn’t worry about air pollution caused by combustion.

Leave A Comment